Additive Manufacturing of Digital Musical Instruments

| Participants: |

Ian Hattwick Marcelo M. Wanderley (supervisor) |

|

|

|---|---|---|---|

| Collaborators: | Cimetrix Solutions |

|

|

| Funding: | NSERC Engage Grant (M. Wanderley) | ||

| Project Type: | Research and Development | ||

| Time Period: | March 2014 - August 2014 (Completed.) | ||

Project Description

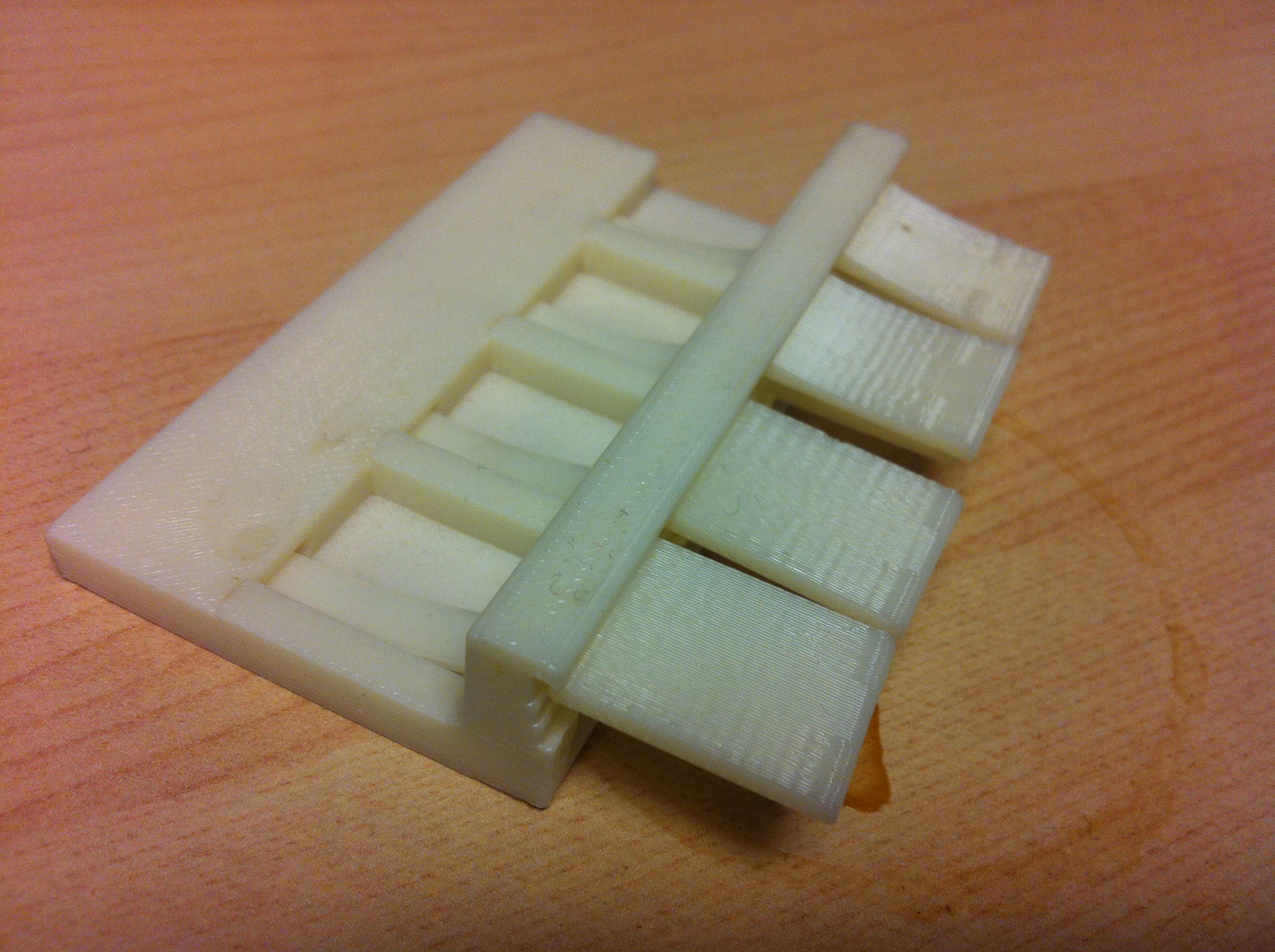

Additive manufacturing (also known as 3D printing) has gained acceptance for a wide range of purposes ranging from functional prototyping to direct digital manufacturing. The most common form of additive manufacturing is fused deposition modeling (FDM) using melted thermoplastic filaments. In this process, successive layers of materials are laid down and fused together to form a monolithic structure. While the additive manufacturing industry has matured in recent years, it has been suggested that its adoption by industry has been hampered by a lack of knowledge over design processes and how components will behave in practice. In the musical instrument industry, there are relatively few examples of additive manufacturing. Most exploratory work in this field has taken the form of reproducing existing acoustic instruments or cosmetic variations on electric guitar bodies and control knobs.

In this project IDMIL researchers team with Cimetrix Solutions, Inc.,one of Canada’s largest suppliers of design consultation, manufacturing services, and equipment for additive manufacturing, in order to explore applications of additive manufacturing towards the design of digital musical instruments.

More Information

Cimetrix Solutions Industry Partner